Supporting you with innovation

Our in-house team of engineers and technical specialists combine experience with innovation to develop solutions that match your growing requirements. From ensuring photocells have the correct lux levels, to developing bespoke designs for special pillars, our team is here to support you.

If you have a technical enquiry about a product you have recently installed or purchased, in the first instance please check our informative product pages, most will have technical datasheets available to download. If you have searched our website and still can’t find the information you’re looking for, please see our FAQs below.

Frequently Asked Questions

Our Technical Frequently Asked Questions (FAQs) will provide you with the answers to some of the most common technical questions we get asked by new and existing customers. To get the answer to a question listed in the FAQs, find the product group that best matches your requirements and click on questions to expand

Photocell FAQs

A standard photocell, also known as a Photo-Electric Control Unit (PECU), is an electronic switching device that is triggered by changing light levels. They switch the supply ON to a load when the light level falls below a given value (usually at Dusk), and switch the supply OFF when it rises above another level (usually at Dawn). A Part Night Photocell will also detect light levels but has an additional clock built in, for switching at ‘OFF’ midnight and seasonal changes such as GMT/BST.

Photocells switch the supply ON to a load when the light level falls beneath a given value (usually at Dusk), and switch the supply OFF when it rises above another level (usually at Dawn). The ratio between the two light levels is known as the switching ratio.

| Positive Ratio | When the ON level is lower than the OFF level (e.g if the load switched ON at 70Lux and switched OFF again at 105Lux, then the unit has a ratio of 1:1.5). As can be seen from Table 1, below positive ratio units have signifcantly longer annual burning hours than negative ratio units |

| Unity Ratio | When the ON and OFF levels are the same (1:1 ratio) |

| Negative Ratio | Most street lighting loads have a warm-up time during which the lamp achieves full brightness. This is typically a number of minutes, and the idea of negative ratio units is that the ON level needs to predict when the lamp will achieve suffcient output, whereas the OFF level is when the light is no longer needed. Typically a 1:0.5 ratio is ideal for this (e.g. turning ON at 35 Lux and OFF at 18 Lux). |

Find out more about photocells and how they work in our KnowHow article

Where possible, Lucy Zodion endeavours to provide you with all the information you require to buy our potocells with confidence. In the case of UMSUG/ charge codes we are making this a consideration to include on all relevant technical product datasheets.

If the code you are looking for is not available on the respective product webpage on this site, please head to the official Elexon website for more information.

Depending on the connection type of the photocell you would like to install, wiring requirements differ. For NEMA and Zhaga photocells, their design considers a simple twist and lock installation that requires no wiring.

For conduit and miniature photocells, we can provide you with a wiring diagram to help you with installation*.

Please contact us and let us know which photocell you require wiring information for – Email: quotes@lucyzodion.com

If you would like more information on how to wire up a socket, please look at FAQ 4, below.

*Although we can provide photocell wiring information for Lucy Zodion photocells, we advise that any electrical work is carried out by a qualified professional.

Most wiring diagrams and intructions for Lucy Zodion photocell sockets are available on the packaging of individual products, however we can provide replacements and advice should you require.*

In the first instance, please take a look at our amenity photocells and accessories pages for wiring information on specific sockets.

*Although we can provide wiring information for Lucy Zodion photocell sockets, we advise that any electrical work is carried out by a qualified professional

Lucy Zodion photocells come in a number of different formats to meet a wide range of connection types. This is usually determined by the way they are mounted or integrated upon/ within the luminaire. The main photocell formats available from Lucy Zodion include:

- Zhaga: The ‘Zhaga’ connection interface has been developed to ensure a specification standard is defined between outdoor LED luminaires and modules for sensing and communication. The standard itself is referred to as Book 18 and helps to bring IoT to outdoor LED lighting fixtures, making it easy to upgrade LED fixtures by adding or changing 24V sensor or controller modules that provide sensing and communication capabilities. Find out more about Zhaga Book 18 and Lucy Zodion photocells that meet the standard.

- NEMA: The ‘NEMA’ socket is partially defined in BS5972 and has become the de facto connector for most one-part photocells. The three connections are the incoming live, the switched live out and a neutral .

- Conduit: This allows for the direct mounting of a photocell onto a Ø20mm thread. Connection is made via wire leads, this arrangement is often used for ‘special’ photocells or where more than 3 connections are required. Due to their wiring format, conduit photocells are ideal for installations where anti-theft/ asset security is a consideration.

- Miniature: Miniature photocells are principally used for direct integration within luminaires. As they operate inside the luminaire, specific consideration needs to be given to the operating temperature. It is possible for the internal temperature within a street lighting luminaire to rise to over 100°C, therefore the photocell needs to be carefully selected to ensure that a reasonable life is achieved. Take a look at our miniature photocell range here.

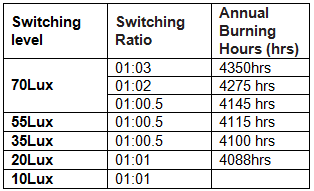

Photocells accurately and consistently control load over a long period of time. They ensure light is provided when ambient light drops to improve visibility, while providing optimum control in clear surroundings to take advantage of natural daylight. The total number of burning hours that a PECU controls each year, is called annual burning hours.

The below Table shows a TYPICAL example of the annual burning hours for PECUs with various switching ratios and switching levels. The actual number of hours, once installed, will vary according to factors such as weather and location of installation.

The SS4D photocell has been designed to control exterior lighting when natural light levels are low (Dusk to dawn). If your SS4D doesn’t switch on your lighting scheme as expected, please check it’s location and that light is being excluded effectively. If testing the photocell during the day, it needs to be effectively covered, which may be done artificailly to simulate darknes. If the unit fails to switch on your light, it is likely that the artificial cover has not adequately excluded all surrounding light. E.g; On a bright summer day, the lux level may exceed 100,000, meaning that over 99.9% of ambient light must be excluded for the device to switch.

If the photocell is obstructed by imposing buildings or heavy forestry, the SS4D might switch on before dusk or after dawn, due to shadowing and lack of ambient light (this could also indicate that neutral has not been connected at installation). If you have installed the unit and the light is flashing, it could be caused by the following factors: If it is daylight and you find the light flashing, it could mean that your Li and Lo have been reversed at installation. If this is happening after dusk, it is likely to be caused by too much light, for example; a nearby window causing the light to reflect on itself.

Find out more about the SS4 or Nightowl range.

The Lucy Zodion range of photocells have been designed specifically for outdoor use as they work based on external light levels. Although Lucy Zodion products are sold for the purpose of outdoor installation, there have been instances where a Nightowl unit has been used successfully for hi-bay lighting, however Lucy Zodion cannot provide support where installations like this are concerned.

For external light switching, we have photocells available for street lighting schemes, as well as commercial, industrial and domestic installations. Find out more about the Lucy Zodion photocell range.

The ratio between the two light levels (Dusk and Dawn) is known as the switching ratio, with switching levels typically;

- 70/35 lux

- 55/28 lux

- 35/18 lux

- 20/20 lux

- 10/10 lux

Find out more about light levels and switching.

We do not show product prices on the Lucy Zodion website. Our products are available to buy direct (B2B) or via our large UK-wide distribution network.

If you would like to enquire about a product, please contact our quotes team and provide a brief description of:

- Product Name

- Product Type

- Quantity

Please send this to quotes@lucyzodion.com

Feeder Pillar FAQs

There are a number of different keys available for our pillars, ranging from the Tri-head keys for the Fortress mini and single door ranges of pillars to the Tee key to suit the Lucy wedge lock, fitted to our double door range and Cast Iron range of pillars.

If in doubt we can always advise if we see a photo of the lock that it is too open.

Please send your pictures to quotes@lucyzodion.com

I know which feeder pillar I need to buy, but I need more information on how to install it. Where can I find this?

We have a wide range of pillars available here at Lucy Zodion, from empty shells to complete pre-wired solutions. If you have bought or you are looking to purchase an empty feeder pillar, we have the following installation recommendations:

Installation on grass: Keep the root attached to install below ground

Installation on concrete:Remove the Root to bolt the Pillar to concrete

If you have purchased, or you are looking to buy, a bespoke pre-wired pillar, please refer to section 2 within our O&M Manual for more installation guidance.

We have a dedicated pre-wired pillar team who can provide you with the assistance you require.

Please contact the team directly on:

+44 (0)1422 317335

If you are looking for electrical installation or wiring advice for an empty pillar you have purchased from Lucy Zodion, unfortunately we cannot provide this. Please consult a suitably qualified civil and electrical engineer.

A special pillar is a specially adapted pillar shell that is made to meet your size and material design specifications. It is supplied empty, like our standard range of feeder pillars.

A Pre-wired & equipped pillar is custom built to meet your specification. It is supplied fully equipped with the components you specify and is ready to install as soon as it arrives on site.

I'm looking to buy a pre-wired pillar and have an idea of what I would like, what information do you need?

To help you specify what you require, please refer to our pre-wired enquiry form.

Our dedicated in-house design team are also at hand to discuss enquiries, click here for more information.

The Westminster has not been designed for EV charging.

Regulation currently requires that points are installed at a height between 750mm – 1500mm above ground so this means that we can not currently use the Westminster for this application. For more information about how the Westminster can be used, please head to the product page

Alternitively, if you want to know how we can meet your EV needs, please head to our EV solutions page

Lucy Zodion can provide standard, special and pre-wired feeder pillars in a host of materials including:

• Stainless steel (Grades 304 & 316) – Grade 304 stainless steel is used for our entire range of Fortress Pillars, which includes; mini, slimline, single and double door. Find out more about these ranges here. There is also a marine grade option (316) available for the Fortress range, which makes pillar shells more suitable to withstand the environmental conditions in coastal areas

• Cast Iron – This is used predominantly for our Heritage or ‘Lucy’ range of pillars, which is then painted making the pillar durable for a lifetime of use. Find out more about our Heritage range of ‘Lucy Pillars’ here.

• Hot Dipped Galvanisation (HDG) – This offers pillars an extra layer of protection to optimise longevity. HDG options are available in our entire Fortress pillar shell range. Find out more about this range here.

• Glass Reinforced Plastic (GRP) – A new offering from Lucy Zodion, our GRP range of feeder pillars are available in the same sizes as our Fortress range and offer a lightweight, low corrosion and high impact resistance alternative to standard stainless steel options. Find out more about the range here.

• Painted – Various options are available for our entire range of feeder pillars, special pillars and pre-wired solutions. We work to any RAL or BS specification and also have custom options, such as anti-condensation paint, please contact us for more information.

These materials are available in the following ranges:

| Material | Range |

| Stainless Steel | Steel Pillars (Mini, Slim Line, Single and Double Door), special and pre-wired |

| Cast Iron | Heritage Cast iron Range |

| HDG | Steel Pillars (Mini, Slim Line, Single and Double Door), special and pre-wired |

| GRP | Sizing as per steel pillar range, special and pre-wired |

| Painted | Steel Pillars (Mini, Slim Line, Single and Double Door), special and pre-wired |

Terminals are supplied as standard in the base of the Westminster to allow you to run up to 50mm Cable (3 or 5 core depending on phase supply).

For more information about the set up, installation and maintenance of the Westminster, please download our O&M manual.

The Westminster has been designed for simple, quick and effective set-up and operation. Providing power from ground to socket in a matter of seconds, it works by extending and locking into an upright position to expose multiple power outlets that enable connection for temporary supply.

The Westminster video will help provide an overview of the way the unit is set-up and used, this can be found here.

Alternatively you can request a copy of the user guide, here.

Yes, depending on the type of pillar and the optional extras you chose at specification, we have a number of warranty schedules to ensure peace of mind that your product will perform as expected. Our warranty offering is as follows:

- Galvanised Feeder Pillars – 3 Years

- Painted Pillars including Cast Iron – 3 Years

- Stainless Steel Pillars – 3 Years

- Westminsters & Pre-wired Pillars – 3 Years on Pillar*

*(1 year components & 2 years on internal wiring)

All Lucy Zodion products carry a warranty for a given period from the date of manufacture.

Lucy Zodion will, at their discretion, repair or replace goods that are returned within the warranty period and subsequently agreed as faulty on inspection by Lucy Zodion.

The date of manufacture is clearly and indelibly marked on each product produced.

This warranty covers defects in material or workmanship that renders the product inoperative or unfit for its intended use. It does not cover physical misuse or damage caused by operating the product outside its intended operating parameters.

Specifically excluded are components that may be considered as consumables such as fuses.

All products must be stored, installed and operated in such a way that damage of a mechanical, electrical or environmental nature does not occur.

It is to be noted that the above warranty is restricted to the repair or replacement of the faulty part and that any resultant consequential loss is not covered or accepted by Lucy Zodion Ltd.

Cut out & Isolator FAQs

Often people call cut outs isolators and isolators cut outs. This confusion is common, however they are different and have their own characteristics.

A cut out has its own British Standard; BS7654. This BS covers all aspects of the cut out from the materials it’s manufactured from, to a series of tests relating to temperature, ingress protection, current, mechanical strength; it even states its physical size.

The main body or enclosure of an isolator isn’t covered by a BS, however reputable manufacturers will still produce the body in the same material as a cut out, which enhances safety.

This is just an overview of the key differences between cut outs and isolators. If you still need more information please take a look at our informative ‘know-how’ blog

Lucy Zodion is known throughout the street lighting industry for it’s expertise in the cut out and isolator field. We have extensive knowledge in the manufacture of high quality fused equipment and can offer assistance to help you find the right solution to match your requirements.

This is why we developed our isolator and cut out questionnaire, which should help us find a suitable product for you. We usually ask you to answer a few questions, as below:

- Product type: Trojan (Midi, Mini, Maxi), Titan, SLF

- Product number: this starts with THM

- If you don’t know the above, we would like to know the following:

- Phase (single or three phase)

- Pole (single or double pole)

- Fuses (1,2 or 3)

- Up/Down (1,2 or 3 up/1,2 or 3 down)

- Number of cables in/out (1,2 or 3)

- Size of SWA cable (6mm to 25mm, 35mm)

- Number of cores (2, 3, 4 or 5)

- Extension box (Y/N)

- Terminals inside ext box. LNE/ LNE+LSNS

- Gland plate (material and number of hols)

- BW gland, Grommets or LM tubes

To complete the questionnaire please click here and submit to orderline@lucyzodion.com

Lucy Zodion manufactures its own cut out and isolator range; both of which comply fully with the relative standards as detailed below. In addition the units are independently tested to give our customers complete confidence that due diligence has been carried out to ensure they are electrically and physically safe.

- Titan Cut outs BS7654

- Trojan Isolators Fuse carrier – IEC/EN 60269-1, isolator – IEC/EN 60947-3

The Comparative Tracking Index (CTI) is the maximum voltage, measured in volts, at which a material withstands 50 drops of contaminated water without tracking. Tracking is defined as the formation of conductive paths due to electrical stress, humidity, and contamination. The maximum test voltage is 600 volts; if failure occurs voltage is typically decreased by 25 volts and the test repeated until a voltage is reached that the sample can pass. The CTI result places the tested product in one of four material groups. The Lucy Zodion cut out and isolator range achieved the top group with a voltage of greater than 600 volts.

The size of the cable is a vital element in determining the size of the cut out or isolator. By knowing the cable size we can ensure the cables can be terminated and provide enough space for the installer to work with the cables.

Cut outs and isolators are devices that are traditionally used in street lighting but can also be used where an electrical device needs protection e.g. festive lighting, fountains, signs etc. For further information about the cut outs and isolators suitable for alternative requirements, please contact our Technical Support team.

I want to replace my existing cut out/ isolator but it is not manufactured by Lucy Zodion, do you supply similar products?

We have an extensive range of cut outs and isolators at Lucy Zodion, which makes us confident we can help you find the solution you are looking for. Our knowledgeable in-house technical department will be able to advise you with a suitable alternative.

Please contact the technical support team and provide them with a photo of the current installation (if possible) and they will endeavour to provide an equivalent solution.

I've found a cut out/ isolator I want to buy but I need to know the price. Where can I find product prices?

We do not show product prices on the Lucy Zodion website. Our products are available to buy direct (B2B) or via our large UK-wide distribution network.

If you would like to enquire about a product, please contact our quotes team and provide a brief description of:

- Product Name

- Product Type

- Quantity

Please send this to quotes@lucyzodion.com

We are able to provide product training on cut outs and isolators along with the rest of our range if necessary. This can be held at either your premises or at our factory and office facility in West Yorkshire.

Please contact us for further information here.

Single pole and double pole refers to the neutral within a cut out or isolator. In the case of a cut out, when the fuse carrier is removed for maintenance, if it is single pole only the live conductors are disengaged, if it is double pole both the live and neutral are disengaged.

Double pole is the safer system as it ensures that the product being protected is totally isolated. Isolators are typically double pole as standard and operate as above.

If in doubt please consult a qualified electrician.

Smart Street Lighting FAQs

Vizion® was the first CMS to be awarded Elexon approval; which was received in January 2009. Since then this has enabled us to help Local Authories save money by accurately switching and dimming lighting profiles for more accurate billing. All our WiMAC enabled ballasts, nodes and collectors have Elexon charge codes and, as we bring new products to market, we continue acquire new charge codes for each device.

The system certification and charge codes including Lucy Zodion equipment can be found on the Elexon site elexon.co.uk. In addition a sample of the Charge Code data is detailed below.

Electronic Ballast 50 0045 0000 100 Lucy Zodion ZEBC45

Electronic Ballast 50 0050 0000 100 Lucy Zodion ZEBC 50

Electronic Ballast 50 0060 0001 100 Lucy Zodion ZEBC 60

Electronic Ballast 50 0070 0001 100 Lucy Zodion ZEBC 70

Electronic Ballast 50 0090 0000 100 Lucy Zodion ZEBC 90

Electronic Ballast 50 0100 0001 100 Lucy Zodion ZEBC 100

Electronic Ballast 50 0140 0001 100 Lucy Zodion ZEBC 140

Electronic Ballast 50 0150 0001 100 Lucy Zodion ZEBC 150

CMS Control Device 98 0001 0000 100 Vizion Ballast Node VB-10 (For use with any Lucy Zodion ZEBC Ballast)

CMS Control Device 98 0002 0000 100 Vizion Collector VC-10 (For use with any Lucy Zodion ZEBC Ballast)

Electronic Ballast 50 0250 0004 100 Lucy Zodion ZEBC 250

Depending on the connection type of the Vizion® unit you would like to install, wiring requirements differ. For NEMA nodes, their design considers a simple twist and lock installation that fits a standard 3 pin NEMA socket, requiring no wiring; directly replacing a photocell. C-Nodes and Collectors have been designed to be installed with lanterns that have an existing 20mm aperture. Their design means they can be retrofit into existing street lighting schemes. We can provide you with a wiring diagram to help you with installation of C-Nodes and Collectors*.

Please contact us and let us know which product you require wiring information for – Email: quotes@lucyzodion.com

*Although we can provide wiring information for Vizion® Nodes and Collectors, it is always advisable to have this carried out by a suitably qualified professional.”

The Vizion® smart street lighting solution is based around UHF radio operating in the 868Mhz range to allow communication from the Collector to the Nodes. Communication from the Collector to the server is over a GPRS connection. No communication within our solution carried over mains.

Whilst on the Vizion® system a menu / graphic has disappeared that used to work OK. What can I do about this?

The system uses a very deep menu / search and database system that interacts with your internet browser’s temporary cache data and cookies. Very occasionally, the cookies etc. can become corrupted or partially deleted by the browser, confusing the system’s on-screen data (the actual database is never affected). To remedy this, clear all your browser’s history/cache/cookies, close it down and restart it and try again.

I have entered the wrong password more than three times and the system has locked me out. How may I remedy this?

Unfortunately, this cannot be remedied by Vizion® Support, it is a locally solvable issue. Clear the PC’s browser history as per the FAQ above.

I have been using the “Group On” facility (by collector). When I re-powered the collector its nodes will not come under its control and continue to day-burn, no matter what instructions I send. How can I get control of my nodes?

The “Group On” facility tells the nodes to ignore all operational commands until a “Group Resume” command is received. Unfortunately, if the Collector has been powered down it cannot receive a “Group Resume” command. To resolve this, another “Group On” command should be sent and allowed to propagate, followed by a “Group Resume”. The Nodes will then follow their operational time profiles.

Presuming that the following is true:

• The collector has communications with the system (Reports/Audit/Collector Operational History Report by COllector).

• The nodes have communications with the collector (Reports/Commmunications/Seven Day Communications Report).

• The collector’s photo-data is valid (Reports/Audit/Photocell Data).

• The Time profile and Seven Day Profile are valid (Administration/Scheduling)

• The Exclusion calendar’s entries for the inventory concerned are valid (Administration/Scheduling)

This issue it particularly relevant to “NEMA Nodes”

Check in the Events Report (Reports/Events/Event Reports/Current Events) to see that there are not “Node Time Reset” reports for the node(s) concerned. You can also check the node’s individual event history. If there are “Node Time Reset” reports, it indicates that the power supply to the node is intermittent. In this case, every time the power is interrupted, the node has to re-acquire its operational time profile. While it is doing this it will turn the lamp on. If this is happens frequently, on many nodes on the same collector, the system will be spending all its time sending out time profiles whilst all the lamps are turned on. The solution to this is to remedy the intermittent supply problem.

This is most likely to be a Collector issue. There could be a number of reasons for this, which can be guided via running the TELNET report. If you are not familiar with the TELNET report, it is advisable to contact technical support for advice

Nodes that I installed previously in the year (and were working OK) have lost communications with the Collector, what could the problem be?

If the surrounding environment or signal path of your installed nodes is populated with a number of trees/foliage, they can alter the node’s ability to absorb and diminish the signal seasonally and in different weather. Without removing this obstacle, the recommended solution is to build around the problem area with SDPs or additional collectors.

As of 1st April 2019, Lucy Zodion transferred hosting of Harvard’s LeafNut interface onto it’s Vizion® CMS Platform. The transfer over to Vizion® enables you to maintain control of your street lighting scheme.

The Vizion® platform utilises the LeafNut structure. Whilst there are some subtle variations in relation to branded assets and reference terminology, users should find the site familiar in operation.

If there is a requirement for training, a service will be available after the initial transfer period. Please contact us in order to understand your specific requirements to enable a tailored training package and cost can be proposed.

Product availability

Lucy Zodion will be manufacturing nodes (Leaf) and collectors (branches) and is currently integrating the transfer of these assets within our production capability. A product matrix denoting LeafNut part numbers and the Vizion® alternative is available upon request.

As previously communicated, whilst we will shortly be able to provide nodes and collectors to support your existing scheme, we are unable to provide a continued supply of ballasts or drivers. Where ballast/driver replacement is necessary we would suggest the use of a suitable DALI ballast/driver and either use a compatible Vizion® DALI-node (product code: F6270), or our specialist interface module to connect to an existing ‘ballast-node’ (Leafnode).

Validating demand requirements is a critical element to establishing an effective Supply Chain. In order to establish the scale of demand, orders can be placed via the Lucy Zodion Sales Order Processing team on:

or by telephone: 01422317337 (Option 1).

Order acknowledgements will be provided and the order will be given a status of “order received, date to follow”, until a confirmed lead-time can be provided. We are looking to set up and continue supply as swiftly as possible.